Product Description:

Polarity Reverse Titanium Electrolytic cell is employed in the sodium hypochlorite generator. The sodium hypochlorite solution is generated by electrolyzing the sodium chloride solution without a membrane and subsequent dilution. It is suitable for sodium hypochlorite generators, water treatment equipment, and electrolytic disinfection equipment, among others.

It is produced industrially through electrolysis with a negligible gap between the anode and the cathode. The solution must be kept below 40 °C (via cooling coils) to prevent the undesirable formation of sodium chlorate. Cl2 + 2 NaOH → NaCl + NaClO + H2O Sodium hypochlorite can be obtained by electrolyzing the salt solution. Due to the simple facility and obvious disinfection effects, the hypochlorite generator has been highly valued. Sodium hypochlorite has been widely used to disinfect drinking water, sanitary wares, dishwares, fruits, and vegetables. Our anode products comply with the standard GB12176-2000 Class A and have been widely marketed.

During this process, a certain amount of hydrogen will be produced. Fortunately, our designed push-type hydrogen discharge technology ensures that the hydrogen is rapidly precipitated on the surface of the compact composite electrode and then discharged along with the rapid flow of the solution.

Features:

To prepare a sodium hypochlorite solution of a specific concentration, our company will examine requirements such as electrode type, electrolytic cell structure, current density, and ambient temperature. Then, we will continuously optimize the electrolytic cell structure and the structure of the electrode plate.

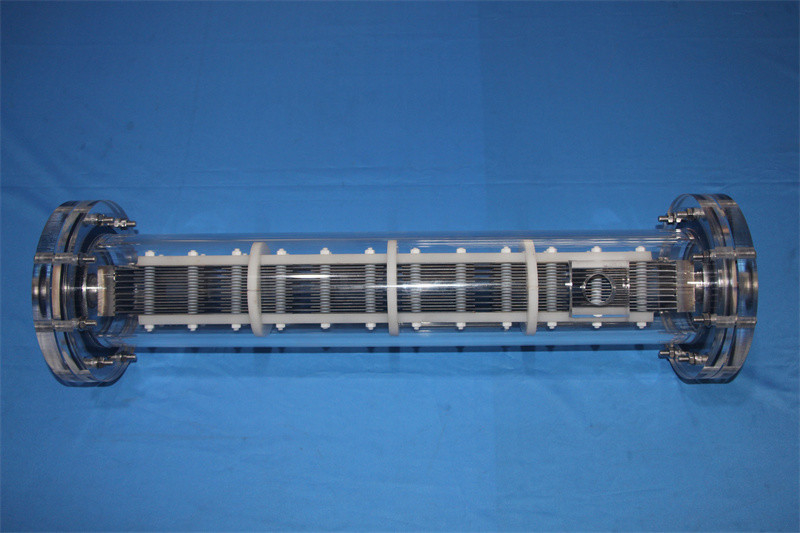

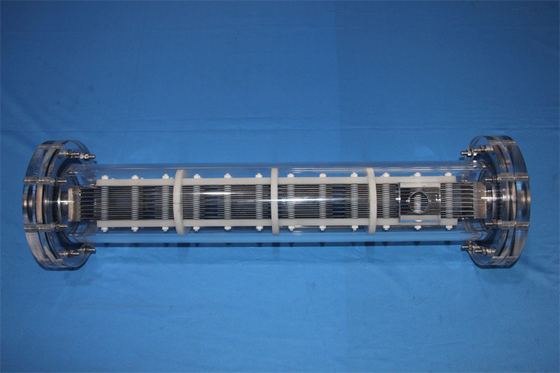

The features of our design are as follows: a tubular tank design with multiple built-in polar chambers, a plate-type bipolar structure electrode group, and an optimized electrode plate coating formula. In the tubular tank design, each polar chamber has a compact structure, which helps disperse the influence of stray currents during electrolysis and improves the electrolysis efficiency.

Each of the tanks and electrode plates is equipped with a production batch and material identification number, enabling the tracking of the usage of each component. The tank body, flange, water inlet, and outlet are all made of thickened acrylic material, making it sturdier and more aesthetically pleasing than normal. With the cooling holes and heat exchange packing rings, the electrolyte flow path is further increased, allowing the effective chlorine concentration to exceed 8500 ppm.

The electrode coating is a nano-scale refined grain ruthenium-iridium mixed oxide coating suitable for the chlorine evolution environment, which has stronger corrosion resistance and a longer service life. During the warranty period, any component that requires replacement within the agreed terms can be done for free or at a cost. For repairs or replacements that exceed the warranty period, they can be returned to the factory for maintenance.

Technical Parameters:

| Parameters |

Details |

| Appearance |

Customized |

| Production |

Sodium Hypochlorite |

| Size |

Customized |

| Application |

Water Treatment |

| Electrolyte |

Brine/sea Water |

| Input voltage |

21~24V |

| Content of noble metal |

10g/m2-50g/m2 |

| Coating thickness |

1~10 Um |

| Input current |

90-130A |

| Coating |

Ru-Ir |

| Titanium electrode type |

Tubular cell, plate electrode |

Applications:

Application Scope

1. Production and preparation of sodium hypochlorite disinfection solution

2. Industrial wastewater treatment

3. Tap water treatment

4. Municipal sewage treatment

5. Breeding and livestock disinfection treatment

6. Other occasions requiring disinfection

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!