Product Description:

Scale, also referred to as limescale, is most often a problem in water-using equipment when water is heated. During the long-term operation of circulating water, hard water scale forms thick deposits in chilled water systems, consequently decreasing heat transfer, reducing water flow, and drawing extra energy. As is known to all, water descaling is a key procedure in commercial facilities maintenance, especially for cooling tower, condenser, heat exchanger, boiler.

As an non-corrosive solution, the electrolytic descaling has be exploited by more and more industries in recent years. Scale removal is achieved through the electrochemical reaction of water electrolysis. During the electrolysis process, the cathode undergoes a hydrogen evolution reaction to generate hydroxide radicals (OH−), creating a high pH environment. Heavy metal ions, such as calcium and magnesium ions, are precipitated onto electrode surface. At the same time, oxidizing substances fromed at the anode side have a certain effect on algae and fungi in the water, thereby inhibiting the growth of bacteria and preventing the adhesion of biological slime.

Features:

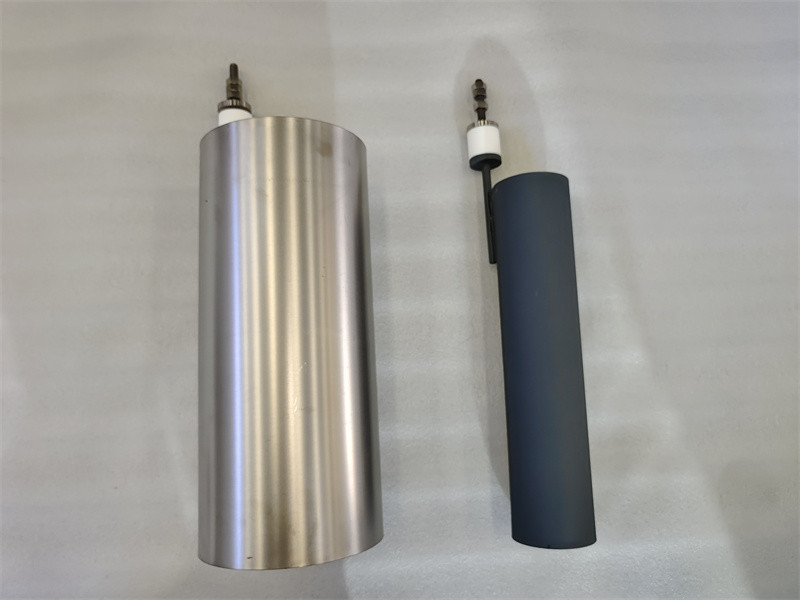

Material: The material of the titanium electrode has a great influence on its performance and service life, and needs to be selected according to the cooling tower environment.

Shape and size: According to the specific application requirements, the shape and size of the titanium electrode assembly can be customized to suit different operating environments.

Coating: In some special application environments, in order to enhance the corrosion resistance of the titanium electrode assembly, it is necessary to coat the surface.

Connection method: Depending on the equipment, the connection method of the titanium electrode assembly will also be different, and it needs to be selected according to the specific situation.

In short, the custom design of titanium electrode assemblies needs to take into account many aspects to ensure that it can exert the best effect in a specific application environment.

Technical Parameters:

| Technical Parameter |

Description |

| Coating thickness |

1~10 Um |

| PH level |

1~14 |

| Input voltage |

0~45V |

| Electrolytet |

Tap water |

| Function |

descaling, chlorine production |

| Current density |

500A/m2 |

| Input current |

0~20A |

| Base metal |

TA1 Titanium |

| Coating |

Ru-Ir |

| Life time |

2~3years |

Applications:

Cooling tower

Packing and Shipping:

Packaging and Shipping of Titanium Electrode Products

Titanium Electrode Products are packaged and shipped in accordance with the following standards:

- The product is securely wrapped in protective material

- The product is placed in a sturdy wooden case

- The box is sealed with strong tape to protect the contents from damage during transportation

- The package is labeled with the customer's name, address, and contact information

- The package is shipped via a reputable delivery service such as UPS, FedEx, or DHL

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!