Product Description:

The Titanium Electrode with Ruthenium and Iridium Coating is widely used to create sodium hypochlorite solutions. It is a perfect fit for sodium hypochlorite generators, water treatment equipment, and electrolytic disinfection equipment. The entire procedure works without the usage of a membrane. Firstly, a low concentration of sodium chloride solution is electrolysed, and without the addition of any chemical, the reaction of the generation process starts.

The overall reaction is the following:

NaCl + H2O → NaClO + H2↑

The separate electrode reaction is the following:

Anode: 2Cl- →2e-→Cl2

Cathode: 2H+ +2e-→H2

Lastly, the solution reaction is the following:

2NaOH + Cl2→NaCl + NaClO +H2O

It should be noted that, during this process, a small amount of hydrogen will be generated. This technology has been equipped with a push-type hydrogen discharge mechanism. This ensures that the hydrogen is quickly removed from the surface of the composite electrode, and discharged along with the high-speed solution.

Features:

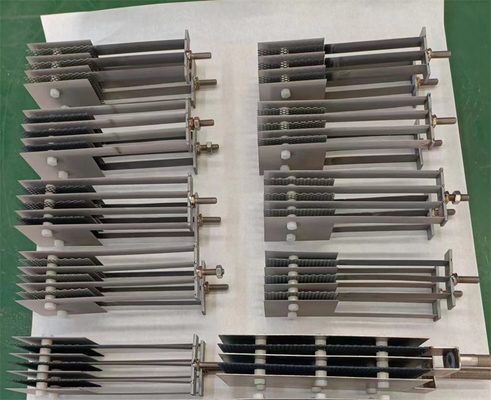

To prepare a sodium hypochlorite solution of a certain concentration, there are certain requirements for the electrode type, electrolytic cell structure, current density, ambient temperature, etc. In the process of cooperating with customers, our company will determine the electrolytic cell structure. The structure of the electrode plate is continuously optimized, and the characteristics of use are as follows:

- The tubular tank design has multiple built-in polar chambers. Each polar chamber has a compact structure, which enables the solution to be electrolyzed more fully. It can disperse the influence of stray currents during the electrolysis process, improve the electrolysis efficiency, and operate under certain temperature conditions and electrical tightness. Under the conditions, the electrolysis efficiency can reach more than 85%. Furthermore, the tank body, flange and water inlet and outlet are all made of thickened acrylic material, which is stronger, more transparent, and more integrated and beautiful than those on the market.

- The design of the plate-type bipolar structure electrode group, with cooling holes and heat exchange packing rings on the electrode plate, provides a long electrolyte flow path. Under a suitable temperature environment, the effective chlorine concentration reaches more than 8500ppm; the optimization of the advanced electrode plate spacing and connection method reduces the impact of connectors on resistance, reduces salt consumption and power consumption, and reduces by-products such as chlorate, so that the effective chlorine output is stable.

- The electrode group coating adopts our company’s optimized nano-scale refined grain ruthenium-iridium mixed oxide coating suitable for chlorine evolution environment, which has a stronger corrosion resistance and a longer service life.

- Each batch of sodium chlorate electrode plates and tanks has production batch and material identification numbers, which can trace the use of each component. During the warranty period, they can be replaced for free or paid. If the warranty period exceeds the warranty period, they will be returned to the factory for repair or replacement of accessories, and after-sales service will be provided.

Technical Parameters:

| Features | Specifications |

|---|

| Appearance | Customized |

| PH level | 1~14 |

| Production | Sodium Hypochlorite |

| Application | Water Treatment |

| Life time | 2~5 years |

| Input current | 1~100A |

| Coating thickness | 1~10 Um |

| Content of noble metal | 10g/m2-100g/m2 |

| Working temperature | 0~60℃ |

| Electrolyte | Brine/sea Water |

| Titanium anode | For Electrolytic cell & Cathodic protection |

Applications:

Sodium hypochlorite disinfection solution is used in a wide variety of applications, including production and preparation, industrial wastewater treatment, tap water treatment, municipal sewage treatment, breeding and livestock disinfection treatment, and other occasions requiring disinfection.

The disinfection solution is produced from a combination of sodium hydroxide and chlorine gas, and is widely used for its anti-bacterial, anti-fungal, and virucidal properties. When used in production and preparation, the solution is used to help ensure the safety and quality of products, as well as reduce the risk of contamination during the production process.

In addition, the solution is also commonly used in water treatment processes, such as tap water treatment, municipal sewage treatment, and industrial wastewater treatment. This is due to the effective removal of bacteria, fungi, and viruses, which can influence the quality of the treated water. The disinfection solution is also used to help control the growth of bacteria and other contaminants, which can lead to higher levels of contaminants in the water.

Finally, the disinfection solution is often used in livestock farming and breeding, as well as other occasions requiring disinfection. This is due to its ability to reduce the risk of infection and disease, as well as help preserve the quality of the livestock.

In conclusion, sodium hypochlorite disinfection solution is widely used across many different applications, as it can provide effective bacteria, fungi, and virus control, as well as help ensure the safety and quality of products.

Customization:

Customized Titanium Electrode Products by Geemblue

Our titanium electrodes are designed to provide superior performance and can be customized to meet your specific needs.

Our titanium electrode products are designed with an input current of 1~100A, and are compatible with brine/sea water electrolyte. We also offer a variety of sizes and appearances to choose from. Additionally, the pH level can be adjusted from 1-14.

Take advantage of our custom titanium electrode products to get the perfect fit for your project. With Geemblue's EC-500 titanium electrode products, you can be sure you're getting the best value for your money.

Support and Services:

At Titanium Electrode Products, we provide technical support and service to ensure the best user experience with our products. Our team of experts is available to answer questions, provide guidance, and troubleshoot any issues. We also offer a variety of resources, including product manuals, online tutorials, and a comprehensive knowledge base, to ensure that you get the most out of your Titanium Electrode Products.

Packing and Shipping:

Packaging and Shipping

Titanium Electrode Products will be packaged and shipped according to the highest standards of quality and safety. All products will be securely packaged in strong, durable materials to ensure they remain safe and intact during shipping. The packaging will also include any necessary labels or instructions for use.

Shipping will be arranged with reliable and reputable carriers who will provide tracking information. Depending on the size of the order, titanium electrode products can be shipped via ground, air, or sea freight. The delivery time and cost will be determined by the customer's specific needs and requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!