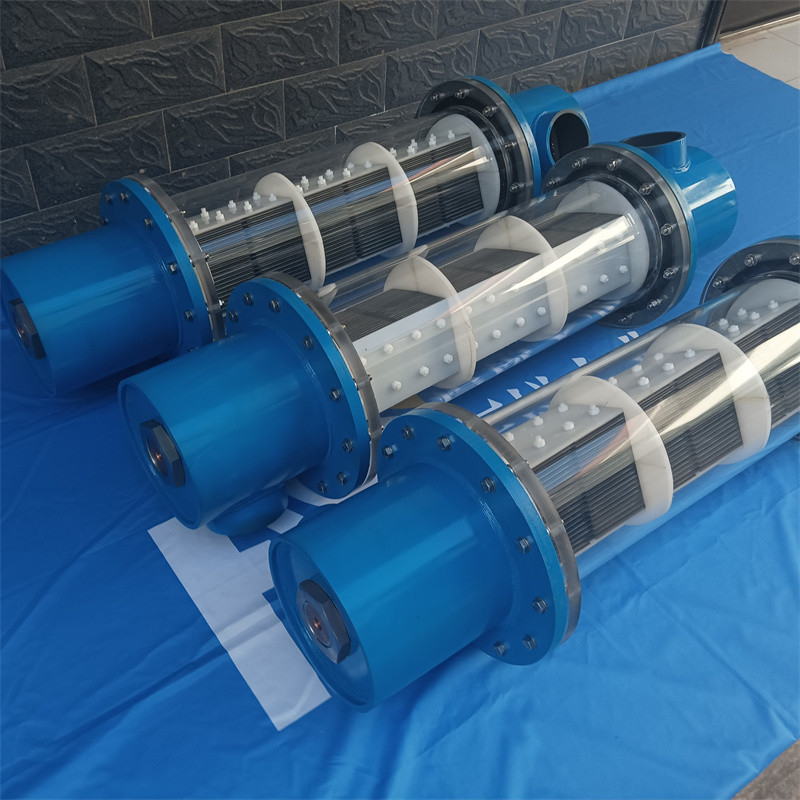

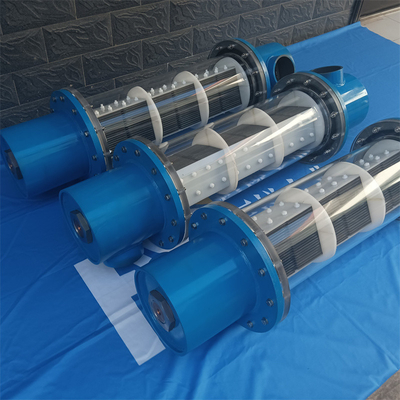

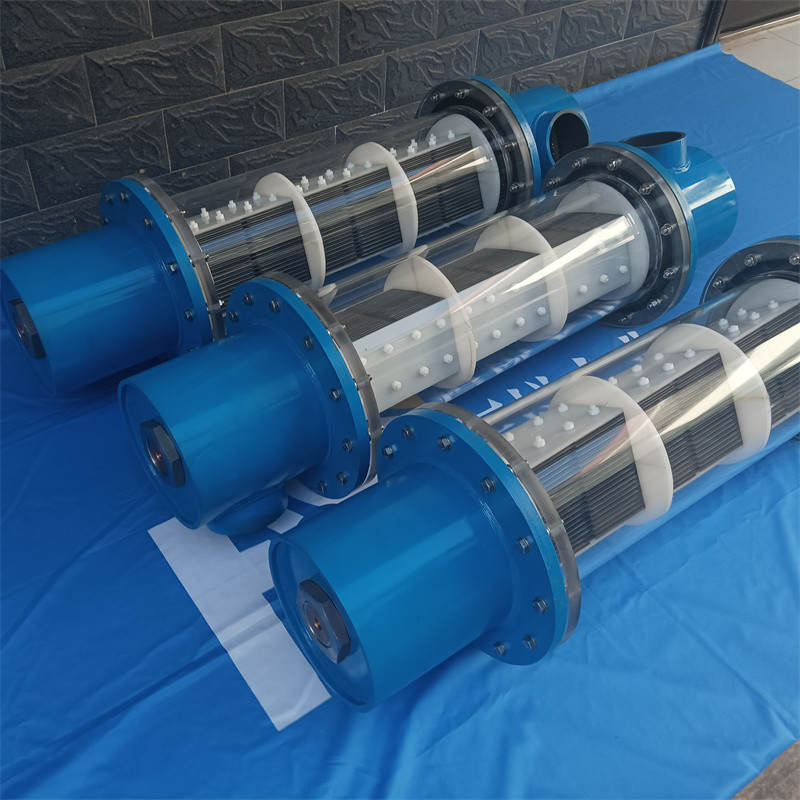

DSA Coating Titanium Electrode

Product Description:

Mixed Metal Oxide (MMO) titanium anode and Dimensionally Stable Anode (DSA) or Dimensionally Stable Electrode (DSE) are terms used to describe coating for titanium anode. This coating is brushed on the titanium substrate and provides effective catalytic activity and a good electrical conductivity.

Brushing precious metal onto the titanium substrate is the key process by which the anode is given it's excellent electric catalytic activity and excellent electrical conductivity.

Features:

Titanium anodes, because of their unique stability in size, ensure that electrode distances between each other never change during the process. This guarantees the electrolyzer is able to run with a stable operating voltage in the electrolyzer.

Titanium anodes also boast comparatively low operating voltage and power consumption, up to 10% lower than the DC power consumption of other anodes.

In addition to their high anti-corrosion capability and long lasting working life, they are able to overcome the problem of graphite and lead anode dissolution in electrolyte, which is often the source of product contamination.

What's more, titanium anodes got a high current density, small overpotential and high catalytic activity, which is capable of improving production efficiency.

Furthermore, a lead anode's deformation and subsequent short circuit, which is usually detrimental to the current efficiency, is effectively avoided with titanium anodes.

Easy to shape, they have a high degree of refinement, and possess reusability in titanium substrate. On top of that, titanium anodes show low overpotential features, which enables electrons and electrode bubbles to be easily excluded from the surface, ultimately resulting in a lower voltage in the electrolytic cell.

Technical Parameters:

The product surface is black with uniform coating, making it strong with low chlorine-evolution potential. It has a long service life, high current efficiency, and a number of other advantages.

It can work with current range of 2000A/㎡~ 10000A/㎡, with working temperature between 25℃ to 80℃. The types of coating metal include Ru, Ru+Ir, Ru+Ir+Sn, and Rare earth+Ru, and the Ruthenium content is between 8g/㎡ to 35g/㎡. The coating thickness is from 2μm to 10μm.

The product is highly durable in any working environment, including extremely acidic or alkaline conditions, such as hydrochloric acid, sulfuric acid, and organic acid.

Applications:

The Chlor-alkali industry uses a diaphragm alkali legal system to produce many different compounds. These compounds include, but are not limited to, chlorates, chlorine dioxide, acidic water electrolysis products, chlorine created from electrochemical sea water, power plant circulating water sterilization for alga growth suppression, electrowinning of metals in chloride systems, electrochemical ionized water electrolysis, and electrodialysis.

Chlor-alkali systems offer a way to produce a variety of compounds for many industries and applications. They are used in pharmaceuticals, cleaning products, and de-icing agents, as well as many other industrial applications. The wide range of functionalities and advantages of chlor-alkali products make them important for many industries.

Customization:

Geemblue EC-100 Titanium Electrode Products are designed to provide superior performance in electrolyzing brine or sea water. With a coating thickness of 1 to 10 um, the titanium anode and titanium electrode can be customized to meet individual customer needs. The coating is Ru-Ir-Pt, and the input current can be 1 to 500A. Our titanium electrode products are renowned for their excellent quality and performance.

Titanium electrode products are shipped in sealed, moisture-resistant packaging to ensure their integrity during shipping. The packaging is designed to protect the electrodes from physical damage and to provide protection against moisture and other environmental factors. All orders are shipped with a tracking number to monitor the progress of the shipment. The shipping time depends on the type of product and the destination.

For international orders, we use a combination of air and ground transportation to ensure the product arrives safely and in a timely manner. All international orders are subject to import taxes and duties, which are the responsibility of the customer.

If you have any questions about the packaging and shipping of our titanium electrode products, please contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!