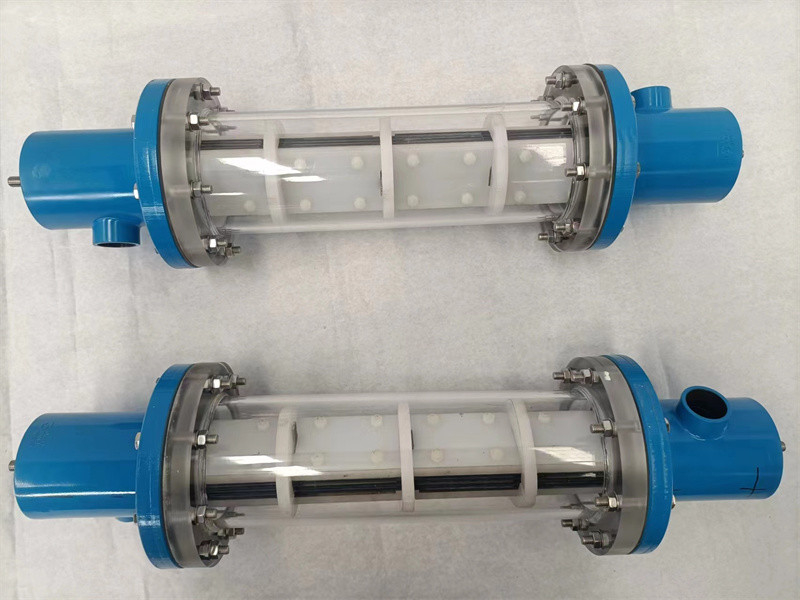

GA1 Titanium Electrode electrolytic cell for drinking water treatment

Product Description:

Coating titanium anode is referred to as Mixed Metal Oxide (MMO) titanium anode and DSA (Dimensionally Stable Anode) and DSE (Dimensionally Stable Electrode).

By brushing a precious metal coating on a titanium substrate, it achieves excellent electric catalytic activity and electrical conductivity.

Features:

Titanium anode electrolytic cell has a very stable size which guarantees that the electrode distances between each other remain the same during the whole process. This enables electrolysis to be performed under stable electrolyzer voltage.

The operating voltage and power consumption of Titanium anode are far lower than that of other electrodes, which can reduce DC power consumption by 10%-10%.

Titanium anode electrolytic cell has remarkable corrosion resistance and a very long working life.

Meanwhile, Titanium anode is capable of avoiding being dissolved by electrolyte like graphite anode and lead anode, and hence preventing product contamination.

By utilizing Titanium anode, it will produce high current density, small overpotential as well as high catalytic activity electrodes, substantially increasing the production efficiency.

The deformation of lead anode causes short circuit problem, which can be avoided with titanium anode and thus improve current efficiency.

In addition, titanium anode is easy to shape and has an extremely high degree of refinement.

Finally, the titanium substrate can be reused saidly.

All these features, such as lower overpotential, make the surface of electrodes and electrode bubbles more easily discharged, thus reducing the voltage used in electrolytic cell.

Technical Parameters:

The product is in a black, uniform coating with strong, low chlorine-evolution potential and long service life as well as high current efficiency. Its working current ranges from 2000A/㎡ to 10000A/㎡, and the working temperature is from 25℃ to 80℃.

It is coated with metal such as Ru,Ru+Ir,Ru+Ir+Sn and Rare earth+Ru. The Ruthenium content is from 8g/㎡ to 35g/㎡, and the thickness of the coating lies between 2μm and 10μm. What’s more, it is applicable for working environment with PH ranging from 0 to 14.

Applications:

The chlor-alkali industry is a large branch of chemistry, employing a variety of technologies. Diaphragm alkali electrolysis, chlorate electrolysis, and electrochemical processes such as acid-chloride or acidic water electrolysis, and electrochemical production of chlorine dioxide on electrowinning metal in chloride systems as well as electrodialysis are all methods employed in this industry. Additionally, electrodialysis can be used for sea water conversion to chlorine, and electrochemical treatment for sterilization of cooling circuits in power plants.

Customization:

Titanium Electrode Products by Geemblue: EC-200

- Brand Name: Geemblue

- Model Number: EC-200

- Place of Origin: China

- Input voltage: 10~48V

- Size: Customized

- Appearance: Customized

- Electrolyte: Brine/sea Water

- Technology: Nano Coating

Our Titanium Electrode electrolytic cell, EC-200, provide superior performance and reliability. Utilizing a nano coating technology, this electrolyzer is designed to handle the toughest conditions and provide superior electrolysis for titanium anode products. With an input voltage of 10-48V and a customizable size and appearance, this titanium anode is perfect for any application.

Packing and Shipping:

Packaging and Shipping

Titanium Electrode products are safely packaged and shipped with the following guidelines:

- All products are securely sealed and placed in a box.

- The box is then placed in an outer packaging and secured.

- Labeling is included on the box with the product's name and description.

- The box is then shipped via a reliable shipping carrier.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!