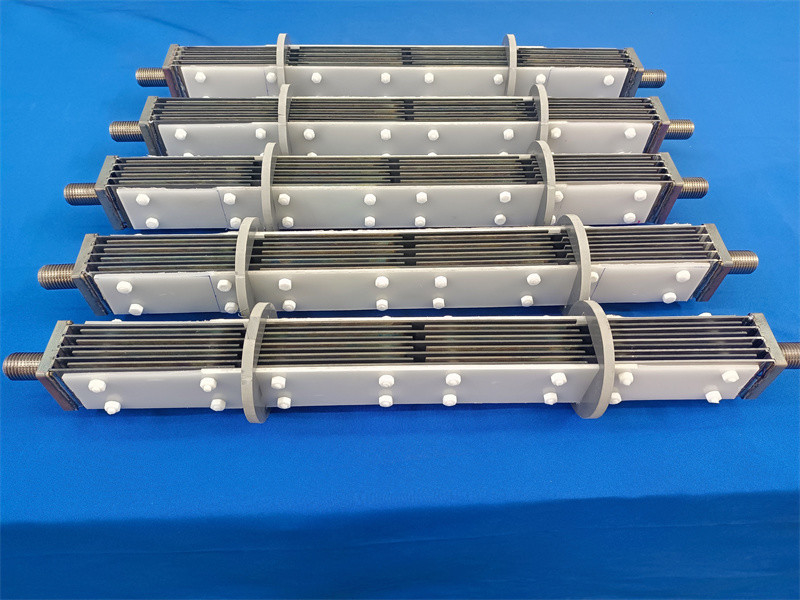

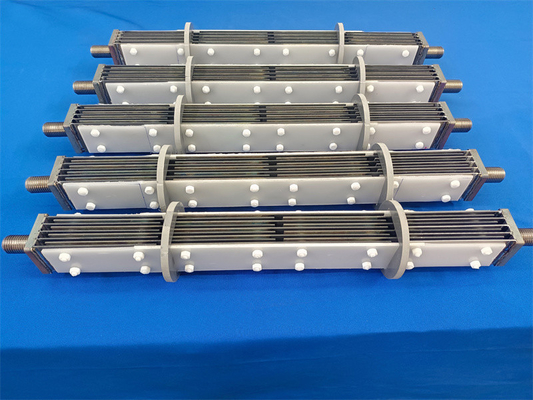

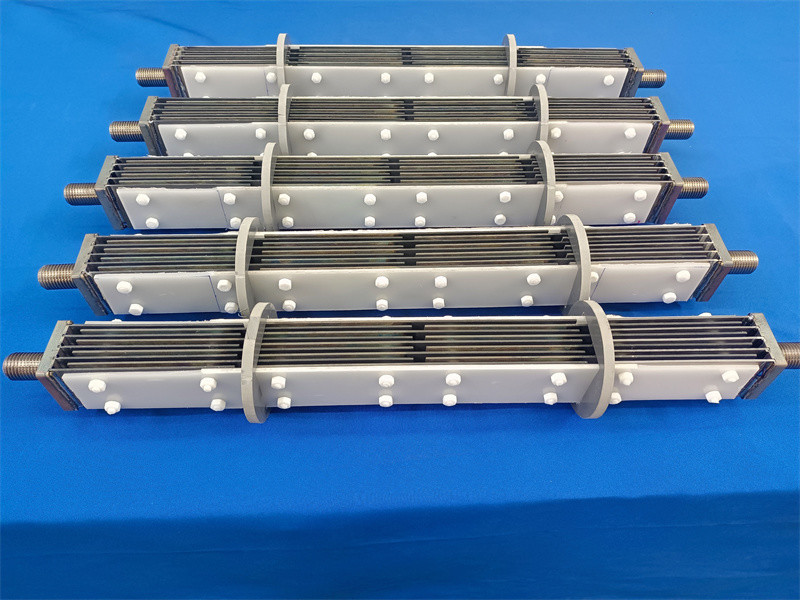

Customized Size Titanium Electrode for water treatment

Product Description:

The Mixed Metal Oxide (MMO) Titanium Electrode, also known as the DSA (Dimensionally Stable Anode) or the DSE (Dimensionally Stable Electrode), is a form of titanium electrode with a coating designed to maximize its electric catalytic activity and conductivity. A precious metal coating is brushed onto the titanium substrate in order to produce the necessary qualities.

Features:

Titanium electrode is quite stable in size, making sure that the distances between electrodes remain unchanged during production process. Its reliable operating offers stable electrolyzer voltage which minimizes the use of DC power by 10-12%.

It also stands out at the top of the list when it comes to anti-corrosion capability and long-term duration. Titanium electrode are far from graphite and lead anodes' dangers of contamination. Plus, its higher current density and low overvoltage leads to efficient electrolysis, eliminating the risk of short circuits.

Easy to shape and highly efficient use of electrodes, makes titanium anode a much desirable product in many industries. Its great economy in use allows for titanium substrate's reuse. Its low overvoltage features enable easy expulsion of the bubble on the electrodes surface, effectively reducing voltage in the electrolytic cell.

Technical Parameters:

Our product has a black, uniform surface coating and offers excellent performance. It has a low chlorine-evolution potential and a long service life. In addition, its current efficiency is notably high.

Working current: The product can withstand current levels between 2000A/㎡ and 10000A/㎡.

Working temperature: It is suitable for operating temperatures between 25°–80°C.

Coating metal: The product can be coated with Ru, Ru+Ir, Ru+Ir+Sn, and Rare Earth+Ru, just to name a few.

Ruthenium content and Coating thickness: The product contains between 8-35g/㎡ of Ruthenium, and a coating thickness of 2-10μm.

Working Environment: This product can perform under a wide range of PH levels, from 0-14.

Applications:

The chlor-alkali industry is an important branch of chemical engineering. The diaphragm alkali legal system technology is widely used in production, such as to produce chlorine dioxide and electrowinning metal in chloride system. Besides, the chlorine, acidic water electrolysis, electrochemical sea water and ionized water electrolysis are also widely used in many areas, such as the chlorine production, chlorate industry and electrodialysis. What is more, the electro-chemical sea water and electrolysis are also useful in the power plant circulating water sterilization and alga removal.

Customization:

Customized Titanium Electrode Products with Geemblue EC-1000

Geemblue EC-1000 Titanium Electrode can be customized with the following properties:

- Brand Name: Geemblue

- Model Number: EC-1000

- Place of Origin: China

- Chlorine Output: 1000g/h

- Size: Customized

- Life Time: 2~5years

- Coating Thickness: 1~10 Um

- Technology: Nano Coating

These customized titanium electrodes are perfect for all your electrolyzer, titanium anode, and titanium electrode needs. Contact us today for more information.

Packing and Shipping:

Packaging and Shipping of Titanium Electrode

Titanium electrode products are packaged using bubble wrap and cardboard boxes to ensure that the product is safe and secure during the shipping process. The box should be labeled with the product name and the shipping address.

To ensure that the product reaches its destination in good condition, a tracking number should be included in the package. The tracking number can be used to monitor the product's location and arrival status.

The shipping company should be chosen carefully to ensure that the product arrives at its destination within the required timeframe. Depending on the size and weight of the product, the shipping cost may vary.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!