Titanium Anode For Brine Sea Water Electrolysis

Product Description:

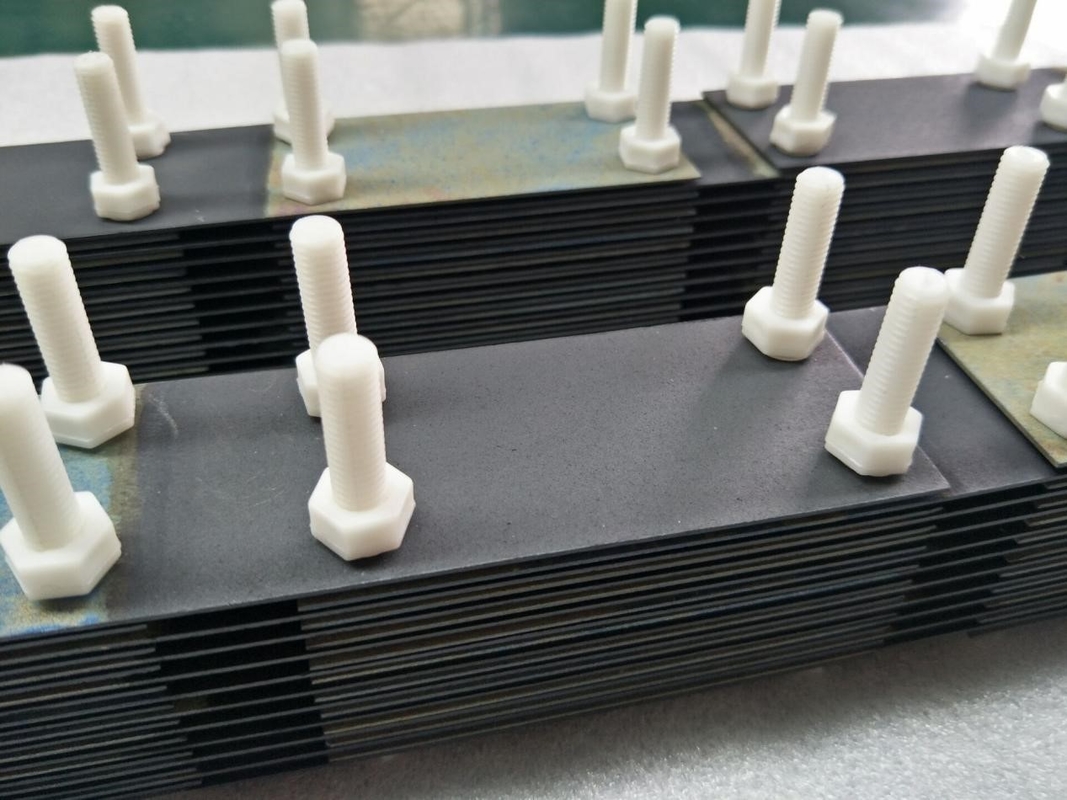

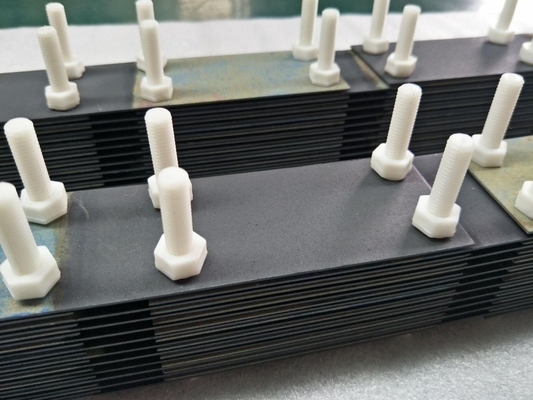

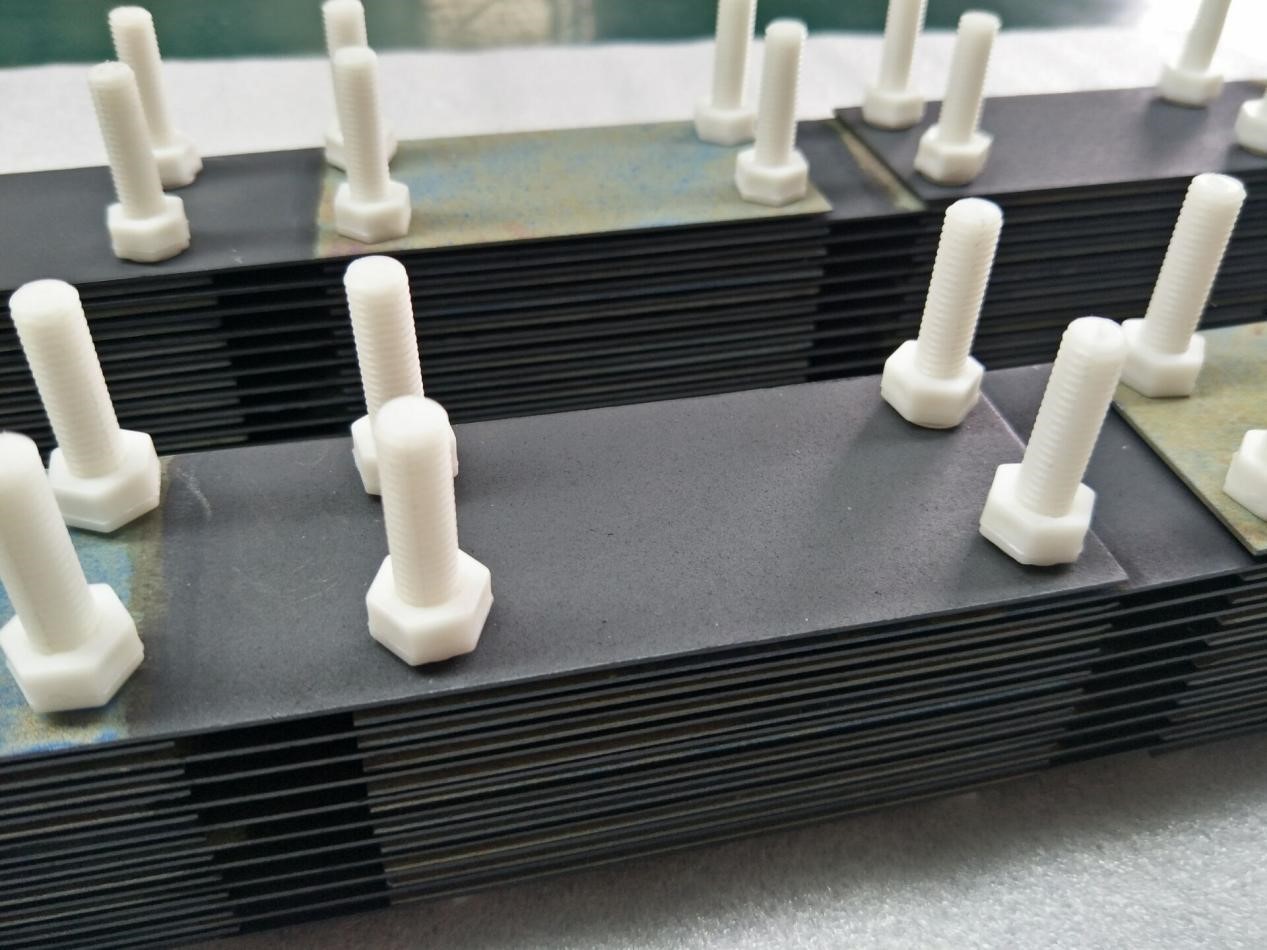

This series of products is a ruthenium iridium titanium electrode, which is made of high-performance titanium material as the main substrate of the electrode sheet and coated with a certain proportion of ruthenium iridium precious metal.

This product is mainly used in the production of chlor-alkali industry, as well as in the electrolysis production of functional water, electroplating industry, ship cathodic protection, etc. In these applications, this series of products have many advantages that exceed the industry average level, such as low chlorine evolution potential, high electrolysis efficiency, and long service life.

For example, in the production of sodium hypochlorite disinfectant by electrolysis, the electrode plates of this series have a much lower chlorine evolution potential than other electrode plates, resulting in lower energy consumption for other side reactions and electrode heating compared to other electrode plates. This ensures electrolysis efficiency while also reducing work energy consumption and extending service life.

Features:

We have developed an innovative chain nano coating process. This process forms a regular geometric structure chain composed of Ruthenium dioxide (RuO2) and Iridium dioxide (IrO2) molecules between the coating and substrate, which ultimately produces a more uniform coating, leading to an increase in the overall service life.

The decrease in chlorine evolution potential of this process is by far the most beneficial aspect. During electrolysis, other side reactions such as the electrolysis of hydroxide ions in water won't be too excessive, thus improving efficiency. An analysis of this series of coated electrode sheets reveals that the chlorine evolution potential is remarkably lower than other similar products, and it performs exceptionally well in the chlor-alkali industry.

Our product also has a higher activity of precious metals. Its precious-metal proportion and binding structure ensure that the reaction efficiency of precious metals is significantly increased. Consequently, the service life of these electrodes has been extended and can operate stably under a variety of conditions, including strong acids and bases. Our tests have led us to believe that under the harsh conditions of 40000 A/m2 current density and 1 mol/L H2SO4 electrolyte, these products are able to work continuously and stably for more than 60 hours.

Applications:

The Chlorine Industry plays an important role in many aspects of modern life. It produces the essential element, delivers many commercial and industrial products that are vital for a healthy environment, and a variety of industrial process agents that can be used for a variety of applications.

Sodium Hypochlorite production is one of the key processes of the industry that is widely used for household cleaning and other applications. In order to produce this agent, the electrolytic production of Chlorine Dioxide is carried out which is then further purified and activated to form Sodium Hypochlorite. In addition, Sea Water Electrolysis and Chlorination is used for the production of industrial chemicals and reagents for various applications, including sterilization and algae control of circulating water.

The Chlorine Industry also helps in the electrochemical deposition of metals in chloride systems, which is widely used as a corrosion prevention and water treatment method. On top of that, Electrodialysis also finds its application in the industry for the removal of salt from water.

Technical Parameters:

The production of sodium hypochlorite is dependent upon the chlorin evolution potential. A lower chlorine evolution potential means a lower working voltage, which will result in lower energy consumption and oxygen electrolysis efficiency. This series of electrode plates have a low chlorine evolution potential which prioritizes chlorine electrolysis. Furthermore, outstanding technology has improved the heating phenomenon of the electrode plates. These factors result in a low working voltage and lower electricity consumption in comparison to other products, with the DC power consumption being reduced by 10%-20%.

Our company evaluates the service life of the electrode plates with each batch of production. After conducting tests, this series of electrode plates has an average working life of over 15000 hours, surpassing similar products by more than 20%.

Customization:

Titanium Electrode Products Customized Service

Geemblue provides customized services for titanium electrode products with model number EC-100. The product is made in China and can be customized in size according to your needs. The coating thickness ranges from 1 to 10 um, and it can be used in brine or sea water. The life time of the product is 2 to 5 years, and the working temperature is 0 to 60℃.

Geemblue titanium electrode products are ideal for a variety of applications, including electrolytic cells, electrolyzers, and electrolytic cell electrodes. They are reliable and durable, making them ideal for long-term use.

Packing and Shipping:

Packaging and Shipping

Titanium Electrode Products are packaged in special cardboard containers to ensure optimal protection during transportation. All orders are shipped using a trusted courier and a tracking number is provided for each shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!