Product Description

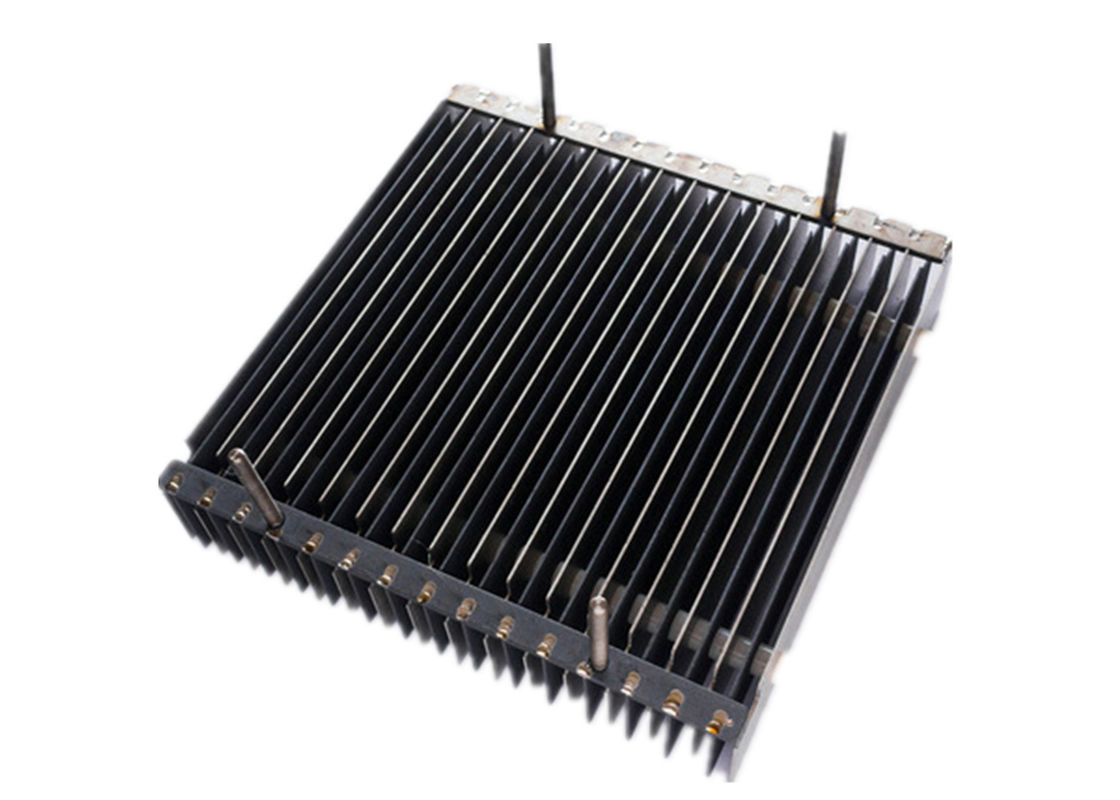

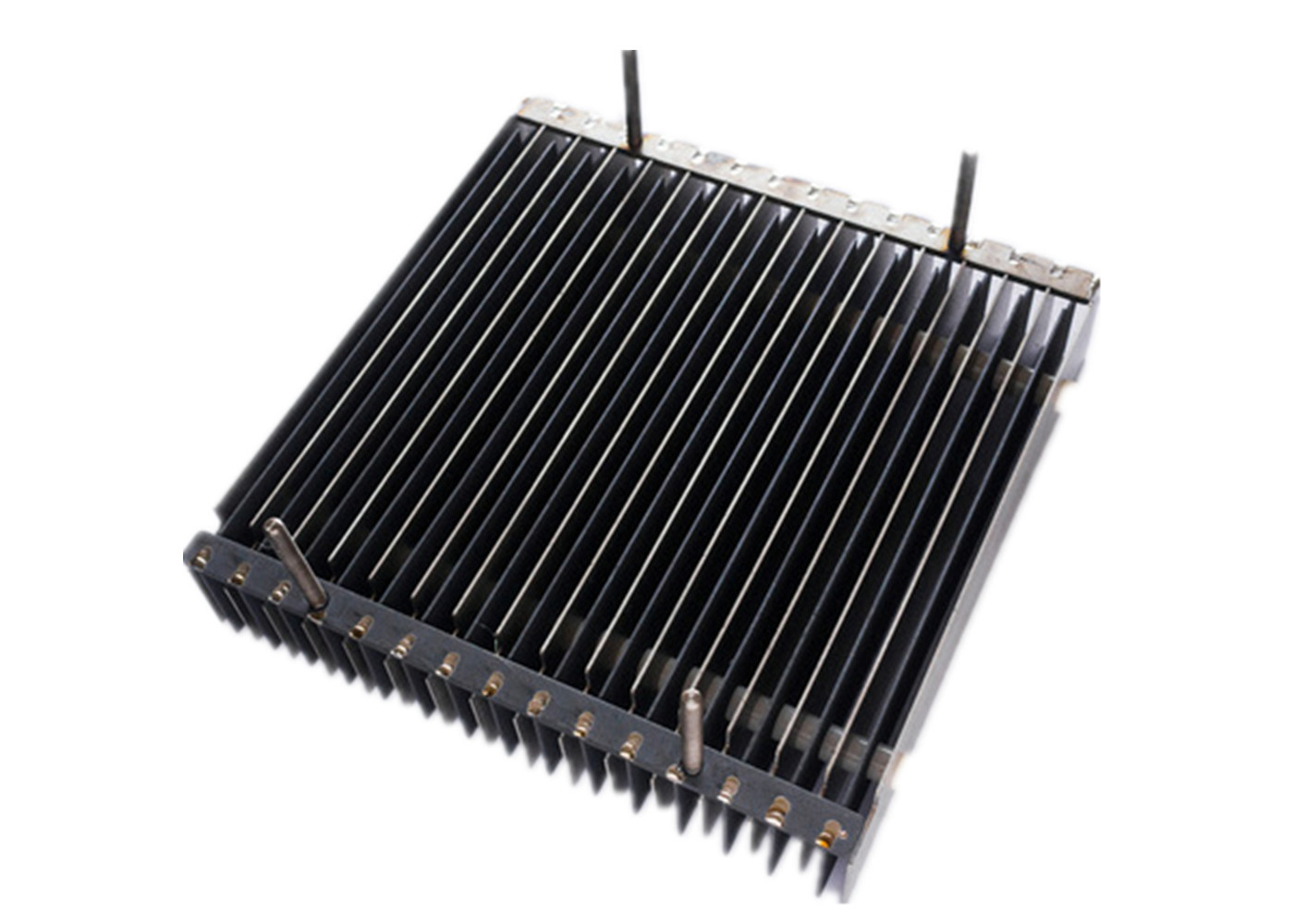

Long Plate Electrode Group Titanium Anode for Cooling Water Treatment Equipment

Introduction:

Electrolytic cell is the most important part for chlorination system, it is key component of generating sodium hypochlorite solution by brine electrolysis.

Electrolytic cell consist of cell body and electrolysis electrode.

Working principles

Electrolysis will generate sodium hypochlorite and ozone, their strong oxidizing power can kill bacteria and insect. In addition, some residual pesticides will be decomposed by electrolysis as well.

This electrode has three outstanding advantages in the chlor-alkali production industry, especially the electrolytic production of sodium hypochlorite.

1. Low electric potential for chlorine separation :

In the production of sodium hypochlorite, the electric potential determines the voltage at the working end, the lower electric potential means a lower operating voltage, lower energy consumption, and less oxygen during electrolysis, increasing the electrolysis efficiency.

2. Low energy consumption in electrolysis

The chlorine electrolysis reaction will inevitably has side reaction, like OH-electrolysis into oxygen. Due to the low electric potential in our electrode, chlorine electrolysis is prioritized, and excellent process improves the electrode sheet heating phenomenon. The operating voltage is low, power consumption is small, and DC power consumption is 10% 20% lower, compared to other products.

3. Longer service life

Each batch of electrode will be regularly tested the service life. The average life of this series of electrodes is more than 15,000 hours, 20% higher than similar products.

Uses:

Electrolyzer inside fruit and vegetable washing machine.

By electrolyzing the diluted salt water, a mixed solution of ozone and low concentration of sodium hypochlorite is produced and used for the disinfection and treatment of bacteria, insect pests and pesticide residues in fruits and vegetables.

Specification

| Titanium Electrode |

| Material |

Gr1 Titanium as substrate, mixed Ruthenium-Iridium-Titanium oxide as coating |

|

Coating ingredient

|

RuO2+IrO2 (special ratio) |

| Technology |

pickling, sintering, nano-coating |

| Dimension & Shape |

Different dimension is available, or according to client's drawing |

| Shape |

Different shape is available, or according to client's drawing |

| Working Parameter |

Current density≤10000mA/M2

Temperature<60°C

PH: 1-14

Fluoride ion concentration: <50mg/L

Coating thickness: ≥1.0um

|

| Remarks |

Titanium anode also called MMO anode, DSA & Insoluble anode

Cathode also be provided

|

| Packing |

Wooden case |

| MOQ |

Flexible, sample order acceptable |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!