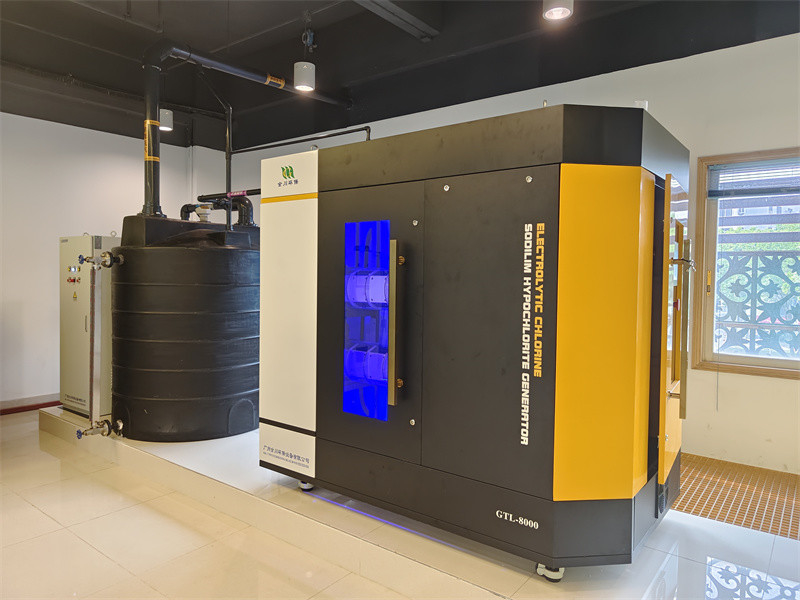

7000-9000ppm Sodium Hypochlorite Generator with 2.5-3% Salt Concentration

Product Description:

Geemblue sodium hypochlorite systems generate sodium hypochlorite from brine by electrolysis. The solution has a concentration of 0.8%, which is not aggressive and is low on minerals - extensive cleaning and de-scaling of the injection nozzles is no longer required.

Conventional sodium hypochlorite loses up to 20% of its chlorine content during storage, however, GEEMBLUE generates 1% sodium hypochlorite, which does not require any additives and maintains its chlorine content's stability over a long period of time.

When generated in close proximity to the process, GEEMBLUE allows for direct storage and dosing of sodium hypochlorite, which prevents accidental spillage of the sodium hypochlorite as well as reducing contact with the operating personnel.

Features:

Fully Automated Operation:

A PLC-based control system provides fully automatic operation of the entire process and monitors key variables to ensure reliable operation of the system. Safety features such as run inhibit during a descaling process, and tank overfill protection are some of the many inherently safe interlocks built into the process controls. The control panel includes a touch-screen human-machine interface (HMI) to provide user-friendly access to operators.

Robust Single-Electrolyzer Design:

Geemblue sodium hypochlorite generator unique electrolyzer design optimizes salt and power consumption while providing easy access to the cell components for maintenance. A clear cast acrylic casing allows for visual inspection, and the improved end-connection cap design minimizes the potential for leaks. The electrolyzer is arranged horizontally for flow optimization; increasing residence time and heat transfer in each cell pass and minimizing hydrogen bubble size. The result is maximum process efficiency while yielding the highest quality hypochlorite solution.

Ease of installation and maintenance Installation Flexibility:

Geemblue sodium hypochlorite generator is perfect for retrofit applications or installation in existing buildings since it can pass through a standard doorway. The floor-mounted transformer/rectifier cabinet on 3.75 kg/h and 5.00 kg/h (195 lb/day and 260 lb/day) is typically installed adjacent to the generator to minimize the length of interconnecting power cables.

Plug-and-Play Convenience:

The electrolyzer system is shipped pre-assembled, pre-wired, and tested to verify hypochlorite production. Once the system is on site the electricity supply, brine solution and process water connections have to be connected to the skid. The common outlet pipe for hypochlorite and hydrogen solution is piped to the hypochlorite storage tank. For these works, the correct installation and regular maintenance, we recommend our specially trained technicians.

Less Maintenance, Reduced Downtime:

All serviceable components are strategically arranged on the skid as to facilitate quick access by maintenance personnel. The process water and brine management subassembly is panel mounted on the skid. The electrolyzer is situated on the frame so that it may be accessed by the operator while standing upright. Flexible hydraulic hose and electrical cables to the electrolyzer make for easy connections and adjustment if needed. Piping and electrical connections are provided for the acid-cleaning system.

Applications:

Chlorination is widely applied for the treatment of potable water, food washing / processing, industrial and swimming & spa pool disinfection. It is an efficient and inexpensive way to effectively remove or neutralize potential hazardous contaminants in water. Chlorination is also used to clean dairies, breweries and cooling towers. This process can maximize the hygienic properties of water, making it safe for various purposes.

For example, in the chlorination process of potable water supply, chlorine or its derivatives are spread out after the filtration process, forming a layer of protective barrier to eliminate possible microorganisms that could cause diseases. In the dairy and brewery industry, Cooling Tower Biocide Treatment can also be applied with the usage of chlorine to prevent growth of harmful bacteria which could impact product quality or spoil it. Industrial chlorination treatments use chlorine to purify water for industrial process application, such as preventing corrosion.

The application of chlorine in swimming and spa pool disinfection is also a very popular procedure for killing any possible bacteria present in the pool water. Chlorine is effective in sanitation, creating an environment in the pool which varies from acid to basic when used in treatment procedures.

Technical Parameters:

Water Softening Process

The incoming water for the water softening process passes through a water softener to reduce its hardness. This helps to reduce the scaling of electrodes and helps to lengthen the cleaning time. Salt is dissolved by the softened water into saturated brine in the tank. Then the saturated brine is diluted to a range of 2.5%-3%, which is then passed through the electrolytic cell to finally get electrolyzed into 0.8% solution of sodium hypochlorite.

The safety of the process is taken into account as the 0.8% hypochlorite solution is stored in a storage tank, and the only byproduct of the process, hydrogen, is ventilated to the atmosphere safely.

For accurate control and dosing, a residual chlorine analyser is put into use.

Customization:

Geemblue GTL-1000 Sodium Hypochlorite Generator

The Geemblue GTL-1000 Sodium Hypochlorite Generator is an electro chlorination system designed for easy and efficient NaOCl generation. It has the following features:

- CE and ISO 9001 certified.

- ATEX approved.

- Minimum order quantity: 1.

- Packaged in a wooden case.

- 380V/60hz 3 Phase power supply.

- 4kw/kg Cl2 power consumption.

- 3.5kg/kg Cl2 salt consumption.

- Requires salt additive.

- Pickling washing mode.

Packing and Shipping:

Packaging and Shipping for Sodium Hypochlorite Generator:

- We use polyethylene drums for packaging.

- The drums are sealed tightly to avoid any leakage during shipping.

- The product is shipped through a recognized courier service.

- The product is shipped within 24 hours of the order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!