Product Description

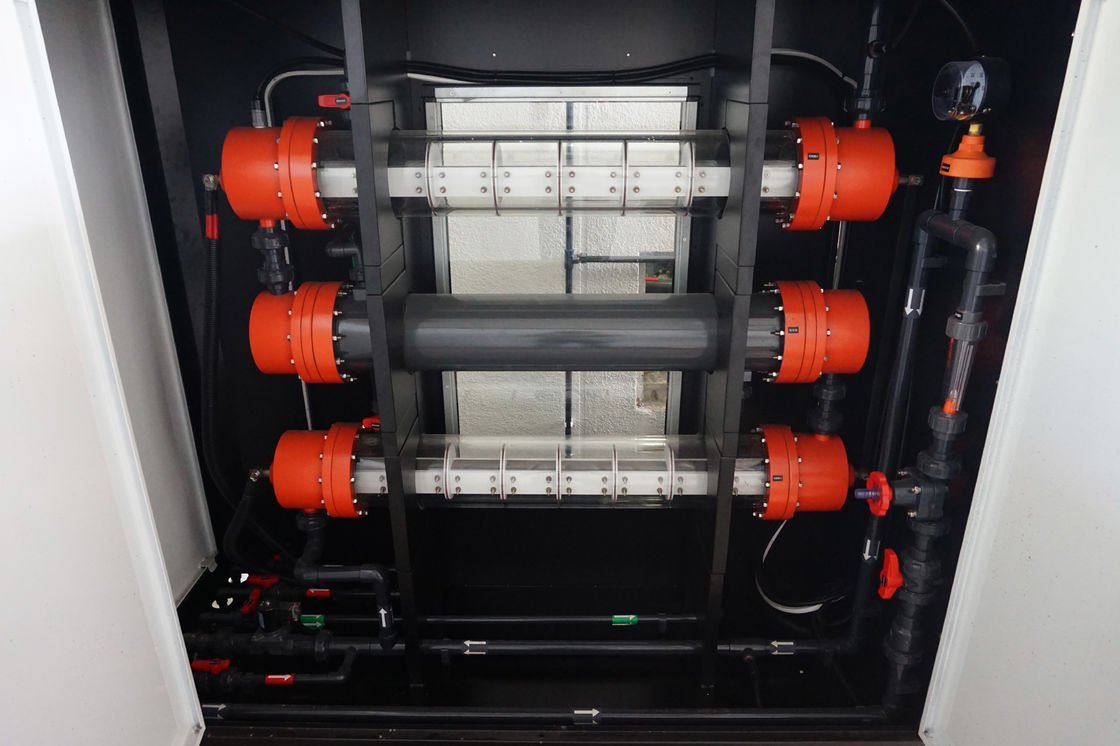

on site chlorine generation with PLC control for Chlorinator plant

Brief Introduction

It is a proven technology to convert ordinary salt (common salt) or sea water, by means of electrolysis into sodium hypochlorite (ELECTRO HYPO) using GEEMBLUE sodium hypochlorite generators (electro chlorination system). It is always applied on-site, at the point of application. No chemicals other than ordinary salt are used throughout the process.

The electrolytic cell is fed a DC current from the rectifier and electrolyzes the diluted brine into sodium hypochlorite solution. Chlorine evolves at the anode surface, while hydrogen and hydroxide evolves at the cathode surface. The secondary reaction of chlorine, sodium and the hydroxyl ion nets sodium hypochlorite (chlorine bleach) at a 0.8% solution. Below 1%, hypo is classified as a non-hazardous chemical although still a very effective disinfectant. The only by-product, hydrogen, is safety vented into the atmosphere.

Principle of sodium hypochlorite generator

Salt solution contains the several kinds of ions such as Na+, H+, when electrolysis, under a certain voltage, as a result of the movement of ions in the electrolyte solution and electrode reaction, the conductive effect occurs, then Cl-, OH- such as negative ion to the anode, and positive ions such as Na+, H+ to the cathode, and the corresponding electrode discharge occurs, thus carries on the REDOX reaction, the corresponding material production. The electrode reaction and solution reactions is

Electrode reaction:

anode: 2Cl- - 2e → Cl2;

cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

NaCl + H2O + DC →NaClO + H2↑

Product process

1. Influent water is passed through a water softener.

2. Using softened water to dissolve the salt in a tank to form a concentrated brine solution.

3. Diluted into 2.5%-3% after filtered (If use sea water as raw material, it will be treated before electrolysis)

3. The diluted brine is electrolyzed to a 0.8% solution of sodium hypochlorite.

4. The 0.8% hypochlorite solution flows into a storage tank.

5. The sodium hypochlorite solution will be injected into the pipe by metering pump.

6. The residual chlorine detector will monitor residual chlorine and return feedback to the PLC center.

7. According to preset standards, the PLC Center will adjust the speed of the dosing pump.

1) The only raw material: salt or sea water which is safety and convenient for transportation and storage, without any volatility and toxicity.

2) Bipolar electrode connection mode, reduced the heat yield, as well greatly reduced the production of sodium hypochlorite salt consumption and power consumption

3) Salt consumption< 3.5kg / kg Cl2 (National standard 4.5); power consumption < 4kw /kg Cl2 (National standard 4.5)

4) Siemens PLC and touch screen, full automatic control

5) Cathode life >20 years; Machine life >15 years.

|

|

Water flow (MLD)

|

Capacity

|

Chlorine concentration (ppm)

|

Dosing rate (ppm)

|

Control

|

Salt consumption

|

Energy consumption

|

|

Huizhou water plant disinfection

|

400

|

30kg/h*3 (two duty one standby)

|

8000

|

4

|

PLC control / full automatic

|

3.5 kg/kg Cl2

|

4kwh/kg Cl2

|

|

Hunan waste water plant disinfection

|

180

|

15kg/h*3 (two duty one standby)

|

8000

|

3

|

PLC control / full automatic

|

3.5 kg/kg Cl2

|

4kwh/kg Cl2

|

|

Guizhou Water plant disinfection

|

40

|

2kg/h*3 (two duty one standby)

|

8000

|

2

|

PLC control / full automatic

|

3.5 kg/kg Cl2

|

4kwh/kg Cl2

|

|

Malaysia Water plant disinfection

|

17

|

3kg/h*2 (one duty one standby)

|

8000

|

4

|

PLC control / full automatic

|

3.5 kg/kg Cl2

|

4kwh/kg Cl2

|

Huizhou water plant disinfection

Hunan waste water plant disinfection

Guizhou Water plant disinfection

Malaysia Water plant disinfection

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!