Product Description

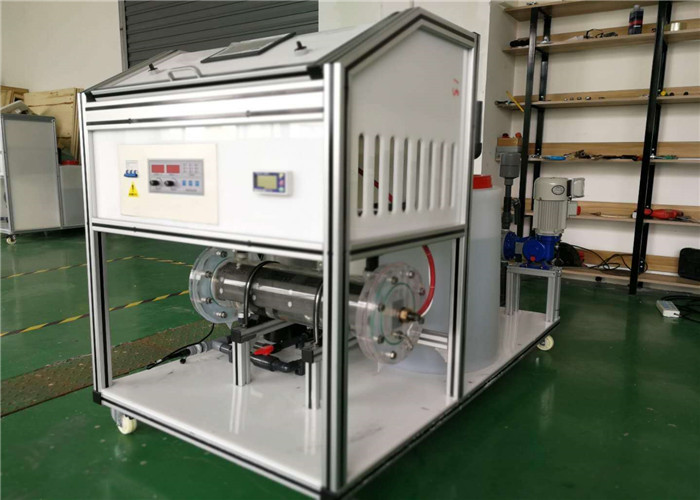

Small Brine Electrolysis Sodium Hypochlorite Generator For Water Treatment

Product introduce:

Sodium hypochlorite generator is a generator to produce sodium hypochlorite by brine or sea water electrolysis, and the whole system is a combination of softener, salt dissolving unit, brine proportion unit, control system, electrolytic unit, storage unit, dosing unit and acid washing unit. It's a system using salt as raw material to produce sodium hypochlorite liquid (0.8%) and dose into water for disinfection.

Generation principle:

The sodium chloride contained in seawater or brine flow between sets of electrodes (anodes and cathodes) in an electrolyzer.

The chemical reactions which take place in the electrolyzer between chlorine and Sodium hydroxide produced by electrolysis.

In the electrolyzer the sodium chloride is completely dissociated into the ions Na+ and Cl-, causes the following electrochemical and chemical reactions:

Electrode reaction:

at the anode: 2Cl- - 2e → Cl2;

at the cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

NaCl + H2O + DC →NaClO + H2↑

Product components

Electrolytic Cell

TA1 pure titanium electrode, with ruthenium &iridium oxide coating which ensure over 5 years coating life, over 18 years base material, reduce the chlorine evolution potential and electricity consumption.

PLC and LCD touch screen

PLC and LCD touch screen we select “Siemens”, electronic components is “ABB” and “Schneider ”, which ensure stable performance

Central control have RS485 communication interface, able to remote monitoring.

Benefit of Geemblue EC system

1. High Safety Level

2. Low Running Cost

3. Full Automatic Operation

4. Accuracy Control Dosing

Comparison between chlorine gas and electro chlorination system (EC system)

| Analysis |

Chlorine gas |

EC system |

| |

Raw materials |

Industrial salt |

Salt + water or sea water |

| Easy to buy |

Easy to buy |

Storage

and

dosing |

Storage |

Pressure cylinder |

PE plastic tank |

| Dosing equipment |

Vacuum chlorine dosing machine |

Pump |

| Dosing accuracy |

low hydrolysis rate, inaccurate dosing |

high accurate |

| Status |

Chlorine concentration |

95% |

0.5-0.8% |

| Status |

strong irritant gas, a highly toxic, explosive and leakage risk |

Stable low concentration liquid |

| Disinfection Byproducts |

easily exceeded of Chlorate or chlorite, leading to contamination of the water quality |

Highly safe disinfectant |

| Smell on water |

Strong chlorine smell |

No smell |

| Cautions |

Leakage prevention measures |

Must be strictly set chlorine leak absorption device |

No special protective measures

water to flush and dilute when leakage. |

| Leak harmful levels |

Gaseous state, once the leak is easy to large-scale diffusion, causing serious social harm consequences |

Liquid with low concentration, easy dilute and flush into the sewage pipes. |

| Maintenance |

Operation and Maintenance |

Professional training course |

No special requirements |

| Equipment costs |

Medium |

High |

| Operation and maintenance costs |

Medium |

Low |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!