It is a proven technology to convert salt, by means of electrolysis into sodium hypochlorite using sodium hypochlorite generator ( electro chlorinator system).

A diluted brine solution is fed through electrolytic cell. When a low voltage DC current is applied, electrolysis occurs and sodium hypochlorite is generated instantaneously. NaClO is generated between 0.2% and 0.8% depending on the application. Below 1% is classified as a non-hazardous chemical although still a very effective disinfectant. The only by-product, hydrogen, is safely vented into the atmosphere.

System Flow Chart

① Influent water passes through a water softener to reduce hardness therefore reducing the scaling of electrodes and lengthening the cleaning time

② Salt is dissolved by softened water into saturated brine in the tank.

③ The saturated brine will be diluted into 2.5%-3%, then pass through the electrolytic cell and finally be electrolyzed into 0.8% solution of sodium hypochlorite.

④ The 0.8% hypochlorite solution flows into a storage tank. Hydrogen, the only byproduct of the process, is safely vented to the atmosphere.

⑤ The residual chlorine detector will monitor residual chlorine and return feedback to the PLC center. According to preset standards, the PLC Center will adjust the speed of the dosing pump.

Compare with other different disinfection method

Chlorine Gas

Strong irritant gas, a highly toxic, explosive and leakage risk

Dangerous transportation and storage

The operator need professional training before operation

Chlorine Dioxide

The raw material hydrochloric acid and sodium chlorate or sodium chlorite may controlled by the government

Dangerous transportation and storage

Most of the chlorine dioxide device have the problem for incomplete reaction

UV

No continuous disinfection ability

Weak disinfection ability in some viruses, such as enterovirus and rotavirus, also hard to detect bactericidal effect

Some bacteria that have not been completely sterilized may recover over time and regain activity

Calcium Hypochlorite

The precipitate formed after dissolution will lead problem for dosing

Increase hardness in water, reduce the quality of drinking water

On site sodium hypochlorite generator

Very effective, economical, safe and easy to prepare and use. This is the latest technology being adopted in most nations.

The only raw material: salt or sea water which is safety and convenient for transportation and storage, without any volatility and toxicity.

|

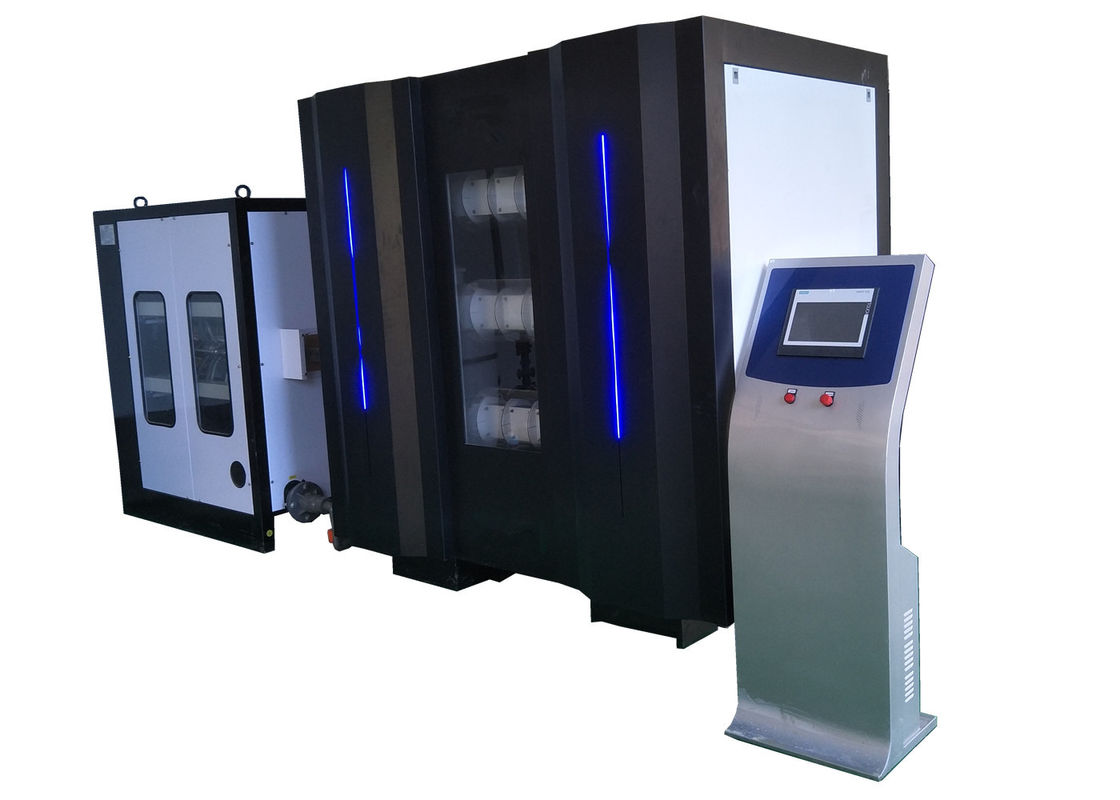

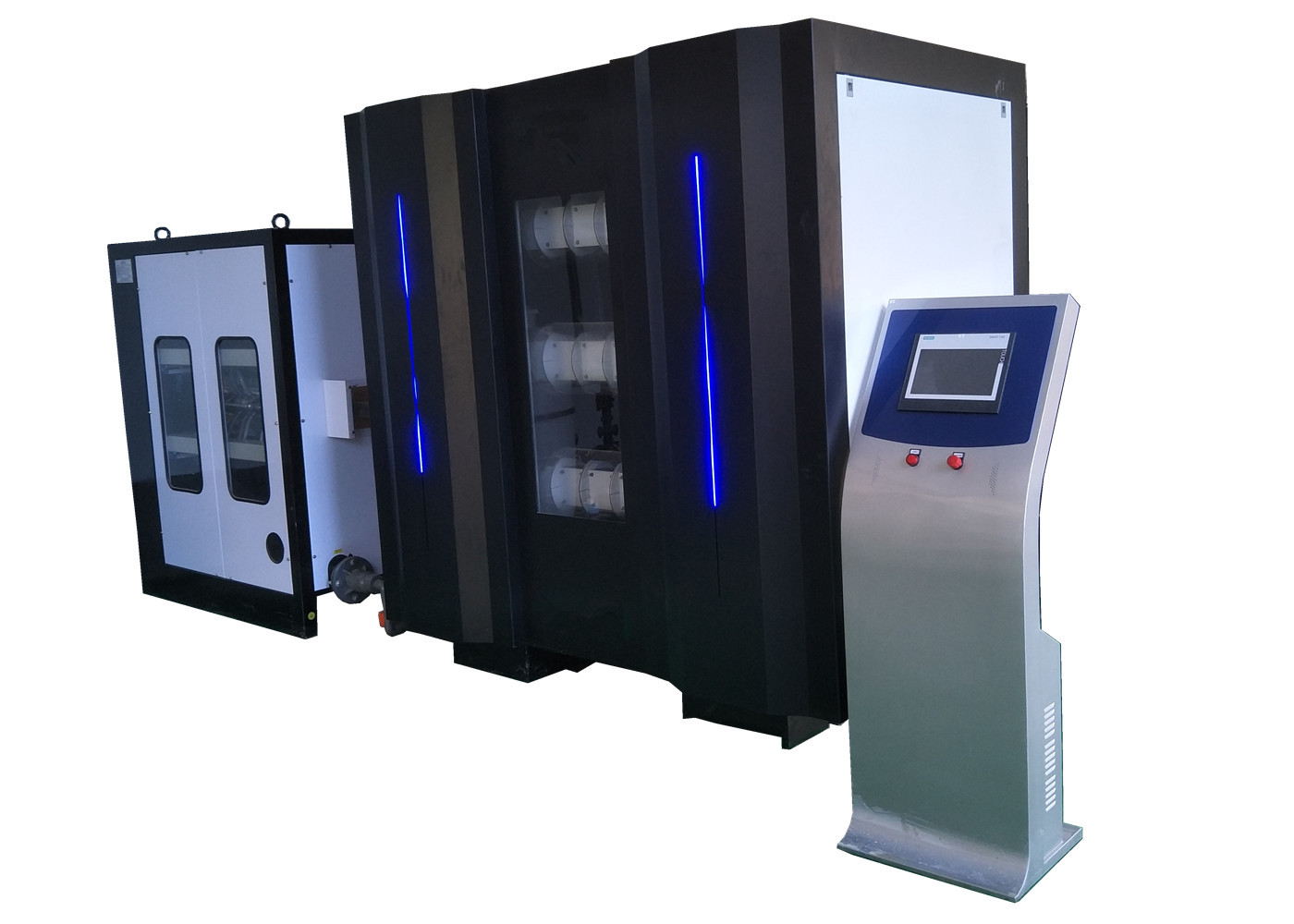

Onsite chlorination system titanium electrode of water electrolysis machine

|

|

|

GB-30kg-NACLO |

|

Product Name

|

Onsite chlorination system titanium electrode of water electrolysis machine

|

|

Chlorine production

|

30kg/h active chlorine

|

|

|

salt, water, electricity

|

|

NaClO concentration

|

5000-8000ppm

|

|

Salt consumption

|

3.5kg per kg Cl2

|

|

|

4.0kw per kg Cl2

|

|

Certificate

|

ISO, CE

|

|

Warranty

|

1 year for the whole machine, 5 years for the electrode

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!