Product Description

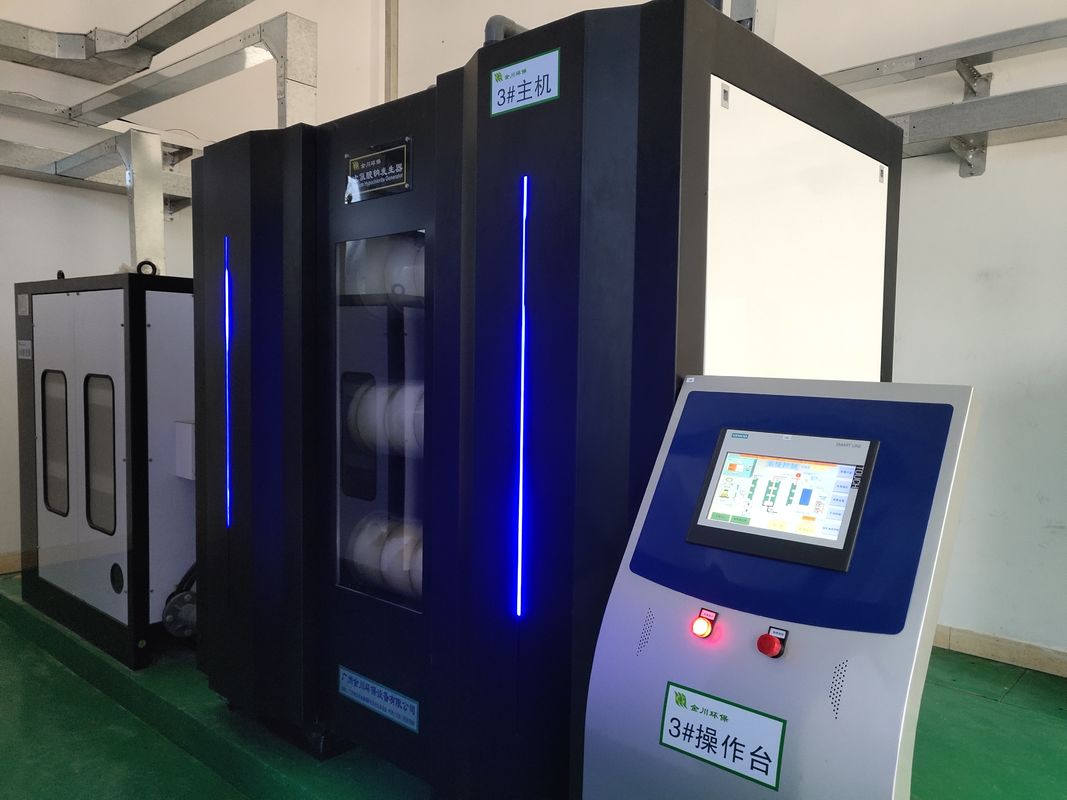

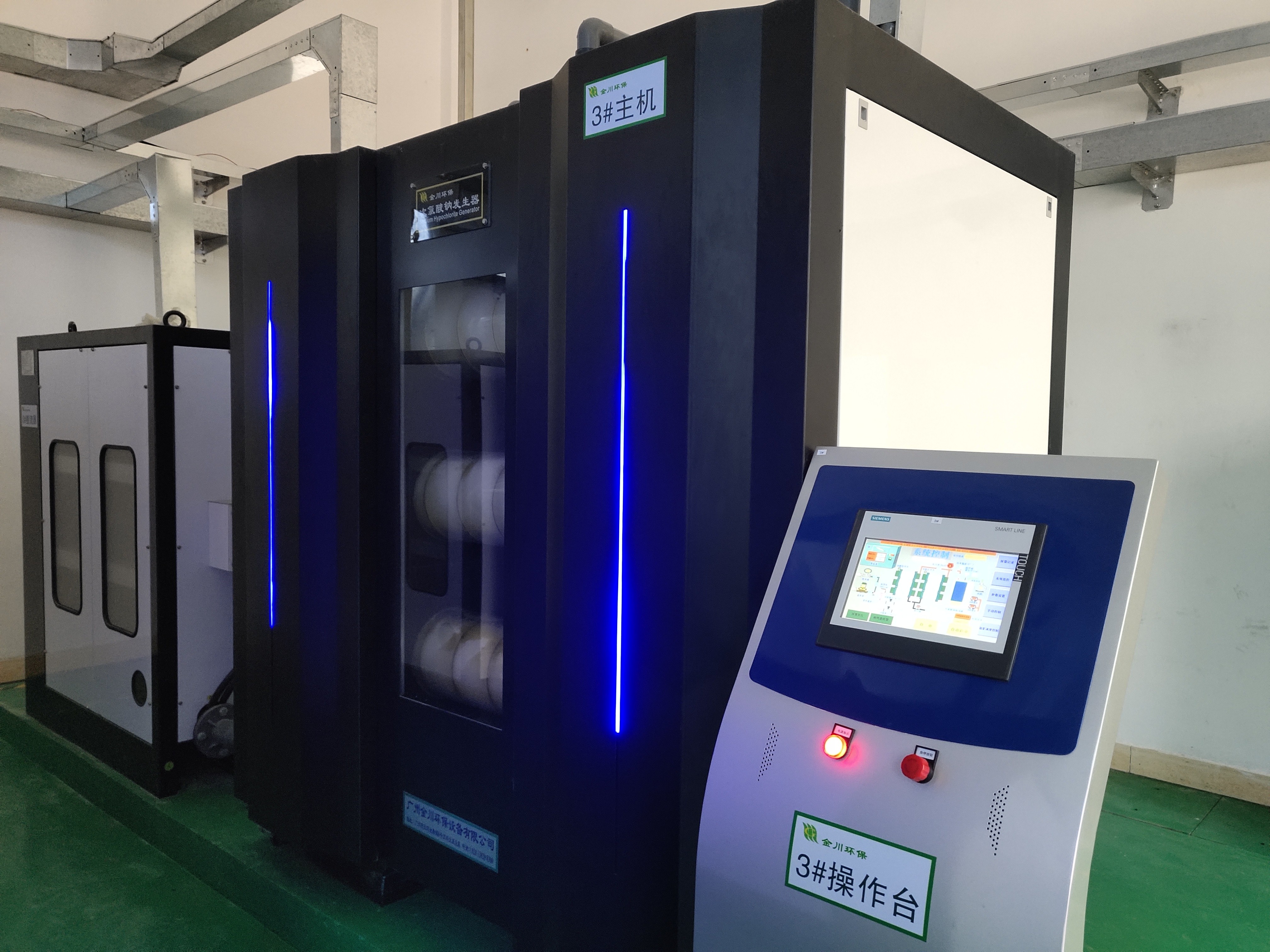

Brine electrolysis Onsite chlorination equipment of sodium hypochlorite generator

Brief Introduction

It is a proven technology to convert ordinary salt (common salt) or sea water, by means of electrolysis into sodium hypochlorite (ELECTRO HYPO) using GEEMBLUE sodium hypochlorite generators (electro chlorination system). It is always applied on-site, at the point of application. No chemicals other than ordinary salt are used throughout the process.

The electrolytic cell is fed a DC current from the rectifier and electrolyzes the diluted brine into sodium hypochlorite solution. Chlorine evolves at the anode surface, while hydrogen and hydroxide evolves at the cathode surface. The secondary reaction of chlorine, sodium and the hydroxyl ion nets sodium hypochlorite (chlorine bleach) at a 0.8% solution. Below 1%, hypo is classified as a non-hazardous chemical although still a very effective disinfectant. The only by-product, hydrogen, is safety vented into the atmosphere.

Electrolysis Reaction Equation

Reaction principle:

NaCl + H2O + DC → NaClO + H2

Electrode reaction:

Anode: 2Cl- - 2e- → Cl2

Cathode: 2H2O + 2e- → H2 + 2OH-

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Product process

1. Influent water is passed through a water softener.

2. Using softened water to dissolve the salt in a tank to form a concentrated brine solution.

3. Diluted into 2.5%-3% after filtered (If use sea water as raw material, it will be treated before electrolysis)

3. The diluted brine is electrolyzed to a 0.8% solution of sodium hypochlorite.

4. The 0.8% hypochlorite solution flows into a storage tank.

5. The sodium hypochlorite solution will be injected into the pipe by metering pump.

6. The residual chlorine detector will monitor residual chlorine and return feedback to the PLC center.

7. According to preset standards, the PLC Center will adjust the speed of the dosing pump.

Advantage of Geemblue Sodium Hypochlorite Generator

Safety Raw Material Added

No chemical required, salt and water only.

No Dangerous Goods Transportation

Chlorine dioxide chemical disinfection, one of the raw material name "Hydrochloric acid" is dangerous material, which is restricetd in the purchase, storage and transportation. Another disinfection too. The on-site electrolytic sodium hypochlorite solution requires only food grade salt which is known as human body needed everyday.

Full Automatic Running

Full computer program, PLC, online chlorine analyser, ensure the residual chlorine in water and make use of every drop of liquid.

Safety Solution Produced

The final product, 0.8% sodium hypochlorite, is recognized as non-hazardous chemical.

On-site Generation And Dosing

Instead of high strength sodium hypochlorite solution which is unable to store for long time.

Low Running Cost

3.5kg salt and 4KWH energy consumption for 1kg available chlorine.

Easy Operation

Central control, able to remote control, the staff can operate after simple training.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!