Product Description

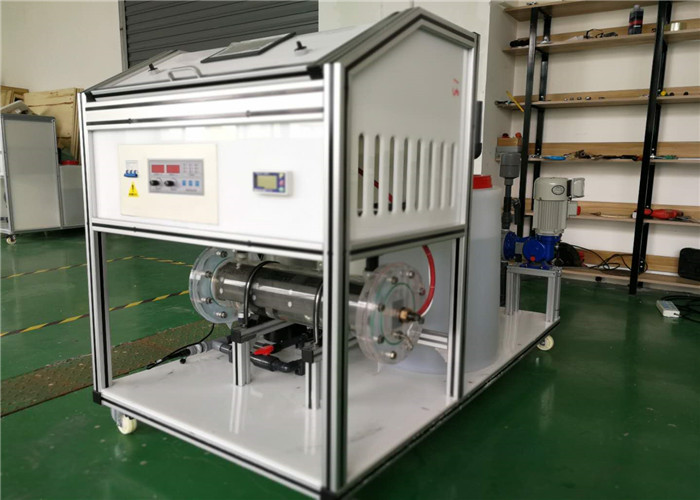

500 g /h Water Treatment System from Electrolysis 2.5% - 3% Dilute Saline Water

Product introduce

Sodium hypochlorite generator is a generator to produce sodium hypochlorite by brine or sea water electrolysis, and the whole system is a combination of softener, salt dissolving unit, brine proportion unit, control system, electrolytic unit, storage unit, dosing unit and acid washing unit. It's a system using salt as raw material to produce sodium hypochlorite liquid (0.8%) and dose into water for disinfection.

Principle

Electrochlorination uses electricity to convert SALT + WATER (brine) into a mixed oxidant solution of sodium hypochlorite and hydrogen peroxide.

Evenly spaced titanium electrodes are placed in a 3% brine solution (NaCl + H2O). When a DC current is applied to the electrodes the brine acts as a conductor between the positive and negative poles. The resulting electrochemical reactions convert the brine into the sodium hypochlorite based mixed oxidant solution.

The electrode reaction and solution reactions is

Electrode reaction:

at the anode: 2Cl- - 2e → Cl2;

at the cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

NaCl + H2O + DC →NaClO + H2↑

Feature and Benefit

♫ Eliminates hazards associated with gaseous Cl2. More stable than bulk sodium hypochlorite.

♫ Safe and clean on-site production.

♫ Safe and economical using only salt, water and electricity.

♫ Eliminate transportation and handling of gaseous chlorine or bulk sodium hypochlorite.

♫ Skid mounted, fully integrated systems.

♫ Automatic, local or remote operation.

♫ Easily integrates with all chlorine analyzers and dose control systems.

♫ Stable and repeatable levels of free chlorine at the end of your distribution system.

Specification

| Model |

chlorine capacity |

Water treatment capacity |

concentration |

flow rate |

salt conversion |

energy conversion |

| GBA-50-NACLO |

50 g / h |

1000 ton / day |

5000~7000 ppm |

10 L / h |

3.5 kg / kg Cl2 |

4 kwh / kg Cl2 |

| GBA-100-NACLO |

100 g / h |

2000 ton / day |

5000~7000 ppm |

20 L / h |

3.5 kg / kg Cl2 |

4 kwh / kg Cl2 |

| GBA-200-NACLO |

200 g / h |

4000 ton / day |

5000~7000 ppm |

40 L / h |

3.5 kg / kg Cl2 |

4 kwh / kg Cl2 |

| GBA-300-NACLO |

300 g / h |

6000 ton / day |

5000~7000 ppm |

60 L / h |

3.5 kg / kg Cl2 |

4 kwh / kg Cl2 |

| GBA-400-NACLO |

400 g / h |

8000 ton / day |

5000~7000 ppm |

80 L / h |

3.5 kg / kg Cl2 |

4 kwh / kg Cl2 |

| GBA-500-NACLO |

500 g / h |

10000 ton / day |

5000~7000 ppm |

100 L / h |

3.5 kg / kg Cl2 |

4 kwh / kg Cl2 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!