Product Description

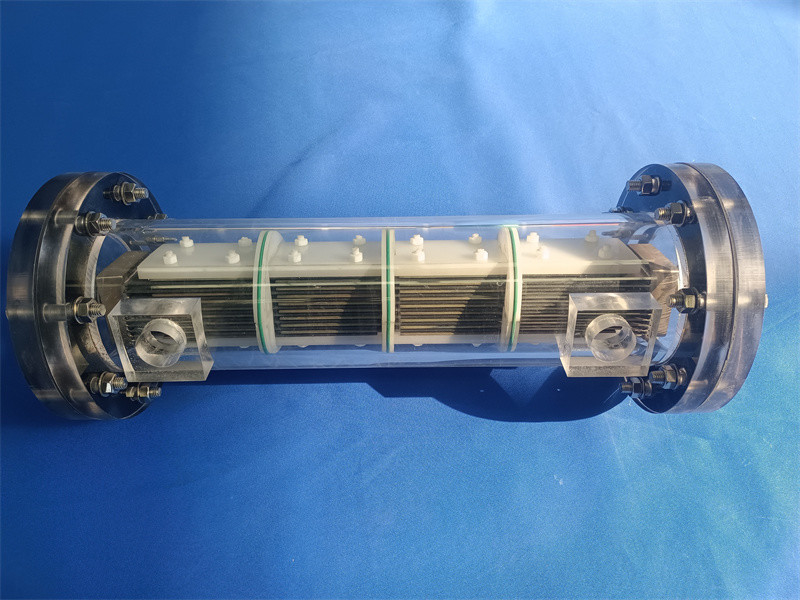

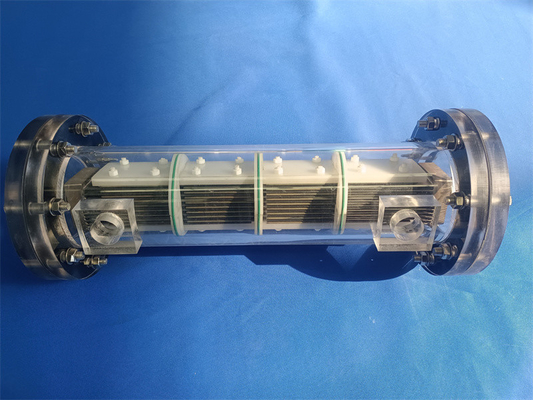

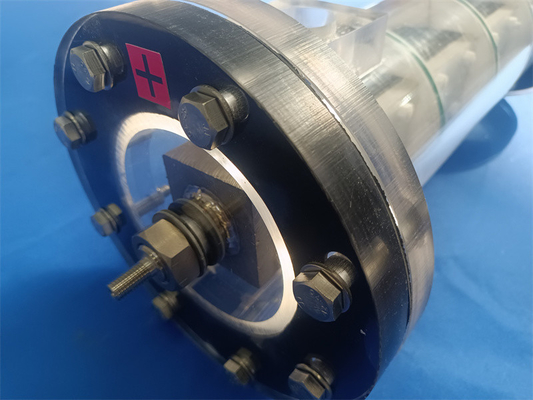

100g/h Electrolyzer For Sodium Hypochlorite

Induction:

The electrolyzer is made of titanium and coated by ruthenium and iridium at a certain proportion.

The product is mainly applied in chlor-alkali industry, the production of functional water, electroplating industry, and cathode protection in vessel etc. Its low electric potential for chlorine separation, high efficiency, long service life makes it an excellent performance, far beyond the average compare to similar products. Take the production of sodium hypochlorite as an example, the electric potential for chlorine separation is much lower than that of the other electrode, as well as the energy consumption and other side reactions, thus ensure the high efficiency for electrolysis while reduce energy consumption and lengthen the service life.

We developed a new coating process:

1. A chain-type nano coating process, it makes RuO2 and IrO2 a regular geometric chain in the coating, and the bonding between coating and substrate become much tighter and firmer, coating becomes more uniform and greatly extends the service life

2.Decrease the electric potential for chlorine ion separation. The chlorine electrolysis reaction is the basic reaction of the chlor-alkali industry. The decrease of the electric potential means that during the electrolysis, other reactions will not be excessively carried out such as the electrolysis of water, and the electrolysis efficiency will be increased therefore. With the advance ingredients in certain proportion and the regular nano-chain structure, the eletric potential of this series of electrodes is far lower than that of similar products on the market, and therefore it has performed exceptionally well in the chlor-alkali industry.

3.High activity. Compared to the old process, the new type of chain coating has high noble metal activity and fast-reaction in electrolysis due to its reasonable precious metal proportion and the combination structure of precious metals.

4.Longer service life. Thanks to a more optimized structure, the service life of this series of electrodes is extended, and it can be continuously and stably operated under strong acid and alkali. Under a current density of 40000 A/m2 and an electrolyte of 1 mol/LH2SO4, Electrode pads can continue to work steadily for more than 60 hours.

Model:

| |

EC-100 |

EC-200 |

EC-300 |

EC-500 |

EC-800 |

| Capacity |

100g/h |

200g/h |

300g/h |

500g/h |

800g/h |

| Brine concentration |

2.5~3% |

2.5~3% |

2.5~3% |

2.5~3% |

2.5~3% |

| Input current |

30~40A |

60~80A |

90~110A |

90~130A |

120~160A |

| Input voltage |

14~16V |

14~16V |

14~16V |

21~24V |

28~32V |

| NaClO concentration |

5000~8000ppm |

5000~8000ppm |

5000~8000ppm |

5000~8000ppm |

5000~8000ppm |

| NaClO output flow |

12.5~20L/h |

25~40L/h |

37.5~60L/h |

62.5~100L/h |

100~160L/h |

Manufacturing processes:

1)Pretreatment:choosing right material, cutting ,welding accordingly , annealing ,cleansing ,acid etching

2) Preparing noble metal: be made up in proportion of mol according to customer's application

3) Brush painting :coated by 12 to15 times

4) thermal decomposition of oxidation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!